International Thermal Systems supplies curing ovens designed to cure coatings applied to one side of a tinplate, aluminum, or steel sheet. #curing

International Thermal Systems (ITS, Wauwatosa, Wisc.) has the experience to design and manufacture a custom wicket oven to support your manufacturing needs. Industrial Conveyor Belt Oven

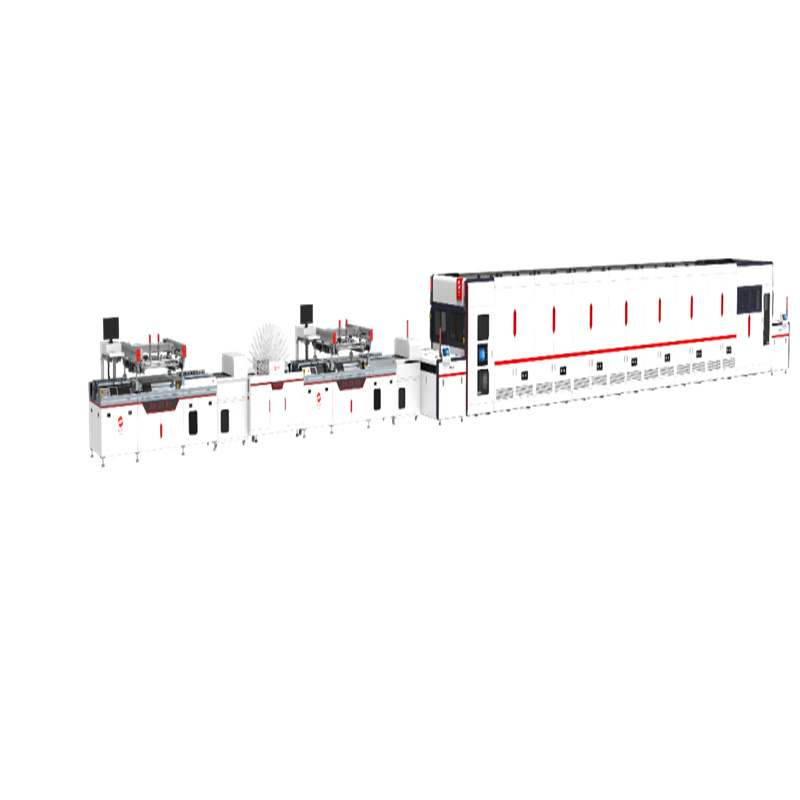

The purpose of a wicket oven is to cure a coating applied to one side of a tinplate, aluminum, or steel sheet. The Wicket Oven derives its name from the wicket carrier that actually supports the non-coated side of the material in a vertical orientation while transported through each zone of the oven. Wicket ovens are engineered to accommodate various material sheet sizes, cure times, and temperatures.

ITS also designs and builds equipment that reduces energy use. For example, ITS manufactures wicket ovens with higher-density insulated walls. Adding thicker high density insulated walls has been shown to minimize shell loss by approximately 30%.

ITS wicket oven features Include:

International Thermal Systems | 877-683-6797 | internationalthermalsystems.com

WolfRayet catalytic gel ovens offer small operational footprints while also providing a way to improve on existing convection curing.

Question: We have a powder coat system.

Industrial Physics' encourages customers in the industrial coatings sphere to consider the energy saving properties of its oven logger kits.

Industrial Powder Coating Oven Copyright © 2023 Privacy Policy [Log On]